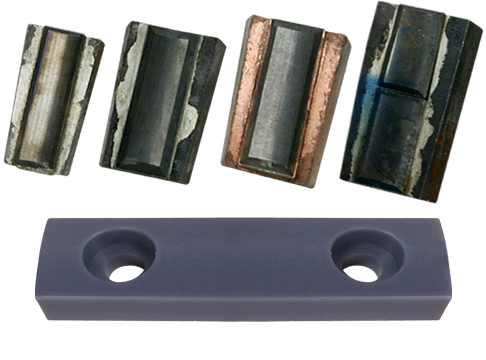

TOOLEX Trepan Tips fit in a slot of the Trepan Head, lock in place and are

the workhorse in the Trepan application.

The Trepan tip cuts a standard .750” groove in your material forming a hole

which yields a core.

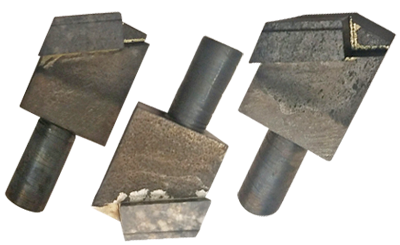

As mentioned, nominal width of the annular cut is .750” wide (actual is

approximately .780”). However, TOOLEX also stocks Trepan Tips of .875” and 1.00” widths.

The TOOLEX Trepan Tips of (.750”) width fit perfectly on our standard

Trepan Head. The TOOLEX Trepan Tips of (.875”) and (1.00”) are used to

cut a wider groove in tough material that will not yield a tight chip or for simply reducing the core size.

Larger TOOLEX Trepan Tips are also used when drilling tighter diameter

holes such 1.750” in which the smaller core could present a chip flow issue.

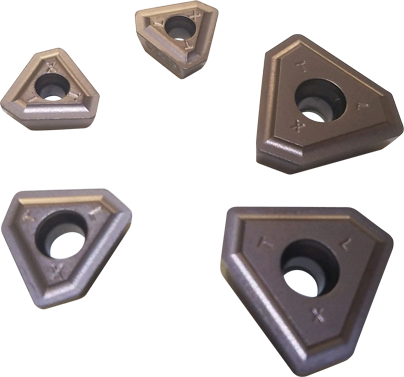

TOOLEX also stocks many of our tips in over/under sizes so that you can drill holes of a non-nominal head size. TOOLEX Trepan Tips are stocked in

either a C5 or C2 grade of carbide and with multiple chip breaker grinds for

different material types drilled and chip formations desired.

TOOLEX also stocks many different Trepan Tips in coatings such as TICN,

TIALN and TIN which can be utilized in cases where your material being

drilled is extremely hard to reduce cutting edge fatigue.

Back to Top |